Peterson Pipes in 10 Steps (+ Awesome History by Mark Irwin)

Posted by Renia Carsillo on 6th Jan 2017

Mark Irwin is a middle school English teacher by day. By night, he and co-author Gary Malmberg are the unofficial Peterson Pipes historians and archivists. For several years, he’s been hard at work on a book documenting the famous company’s stories.

Irwin has spent six years compiling hundreds of photographs, catalogs, records and other materials from the Peterson archives. He’s worked side-by-side with Peterson collectors around the globe. The result is a 120,000 word behemoth of a book. Its contents document the unique story of one of the longest-running companies in the tobacco pipe world.

Irwin’s long-awaited book has three sections: one each for the company’s history, pipes, and the pipe-smoker’s experience. I spent a couple hours peppering Irwin with questions about his work. What follows are a few of those answers, which present a picture of Peterson Pipes that will delight both long-time collectors and new fans.

Delving into Peterson History

Renia: What kick-started your interest in Peterson Pipes?

Mark: When I first started smoking a pipe, my best friend, a very bright young novelist, gave me a hard time for not having a Peterson Pipe in my collection.

He was shocked.

He put me in the car, and we drove from Tulsa, Oklahoma to Norman, to a B&M so I could pick one out. I remember him quoting the famous slogan:

“The thinking man smokes a Peterson pipe.”

Our bromance was based on a shared love of great literature, theology and film. It was an important moment of awareness, or conversion, in my pipe-smoking life.

In those early days, I would go into a B&M and grab any information I could find. I wanted every scrap of knowledge about this thing I love. It’s been a passion of mine ever since.

Renia: Tell us about the Peterson book. How did it come to be?

Mark: Somewhere C. S. Lewis says we tend to write the books we want to read. I'd taken a break from pipes to explore cigars but came back to them after a couple of years. Then in the summer of 2009, I took a trip to Ireland and visited the Peterson factory in Sallynoggin and their old Grafton Street store in Dublin. When I got back, as I looked around the forums and searched the usual bibliographies, I could not figure out why more hadn’t been written about Peterson.

I think the late, great Bill Unger helped start the process by publishing some of my writing in The North American Pipe Society’s The Pipe Collector. Before long I was blogging for Luca di Piazza of NeatPipes.com, mostly under the “Charles Mundungus.” And I self-published Pipe Smoking in Middle Earth (2012), followed by a little book for Luca, The Five Laws of Pipe Companioning (2013), which had the cumulative effect of making me believe I might do something on a bigger scale.

The first person I contacted with the Peterson book idea was Scottish blogger and Peterson collector, Jim Lilly. I offered to be the goffer and to organize the information because I believed there were dozens of Peterson collectors who would want to contribute. Jim knew both “Trucker” Chuck Wright (now deceased), who was very active on the pipe forums, and Gary Malmberg, an estate pipe merchant specializing in vintage Petes. Between the four of us, I felt we had a pretty good editorial board. But by the time we made it to the writing process a year or so later, it was just Gary Malmberg and myself. With his strong interest in history, it was only natural that he would concentrate on the history and early pipes, while I would write about things like craftsmanship, design language, and more recent pipes.

I don’t believe in fate, but the extraordinarily serendipitous nature of the whole process continues to reinforce my belief that Grace –or the Tao, if you will – is always there. It’s important just to be aware.

Renia: Can you give me a sense of the amount of research that was involved, it must have been substantial?

Mark: I’m not sure “substantial” is a strong enough word. It's hard to quantify the massive amounts of data we’ve sifted through over the past six years. We have accumulated and digitized catalogs from every decade of the company’s 150 year-plus history, created spreadsheets documenting the examination of hundreds hallmarked pipes from the company’s beginning, talked to anyone with expertise in Peterson. The photography archives alone are unreal.

When Angela Fortune still worked for Peterson, she began sending me little batches of scans from things she’d find in the archives, encouraging me to the realization that we’d have to go and have a look for ourselves.

So in the summer of 2013 Angela found us a B&B near the factory in Dún Laoghaire (a suburb of Dublin), and Gary and I, along with my wife – a research librarian – went for an intensive, crazy-fun and wholly unforgettable week. While my wife went through every drawer and cabinet in the “Museum” and became friends with everyone in the office, I did interviews with over a dozen active and retired employees. The company was very welcoming. Tom Palmer, CEO of Peterson, who has been our partner throughout the entire project, gave us carte blanche to the factory floor, office and archives, proving to be a remarkable and attentive host. His son Sean did the first round of interviews for us which proved so instructive that I knew we’d have to go just to do in-depth interviews with current and retired artisans.

Peterson has always been a small, tight-knit company, and the people who work there have often thought of themselves as part of the “Kapps” family—Kapp & Peterson being the original name of the company. This becomes really apparent in the un-self-conscious way the company has documented itself over the course of their history.

One of my favorite examples of the serendipitous nature of the whole project concerns Charles Peterson’s daughter, Isolde, who followed her father’s concern for the welfare of others, becoming a life-long leader for Amnesty International in Ireland. Through our research, we found she was godmother to another local family, who held an extraordinary scrapbook of pictures of Charles Peterson and his family. Many of these photographs will be published for the first time in the book.

Renia: What were some of the challenges you encountered while putting the book together?

Mark: Data mining, especially as regards pipe smoking and manufacture, is always a challenge, and in some ways, it’s only getting worse in the digital age. It takes an incredible amount of patience and highly-exacting standards to do historical research correctly. There is an incredible amount of misinformation in the pipe-smoking community that just seems to get recirculated over and over again. A second continuing challenge has been creating high-resolution, fine-art, book-quality images and illustrations to accompany the text. Gary and I are both amateur photographers and writers with strong backgrounds in academia, which has definitely been an asset.

How a Peterson Pipe comes to be

Renia: Can you explain the manufacturing process for Peterson today? It’s somewhat unique, as compared to most other large brands, right?

Mark: The steps in the creation of a Peterson pipe haven’t changed much over the decades, aside from better ergonomics and equipment. I suspect they’re not all that different from any other large brand, but I don’t like to call Peterson a “factory” because most of the work is done by hand. When I think of a factory, I think of anonymity and robots, but there are less than 25 people on the Peterson factory floor, and while most of the artisans are only responsible for one or two steps of the production process, at the end of the day it’s still a labor of love for the people at “Kapps.”

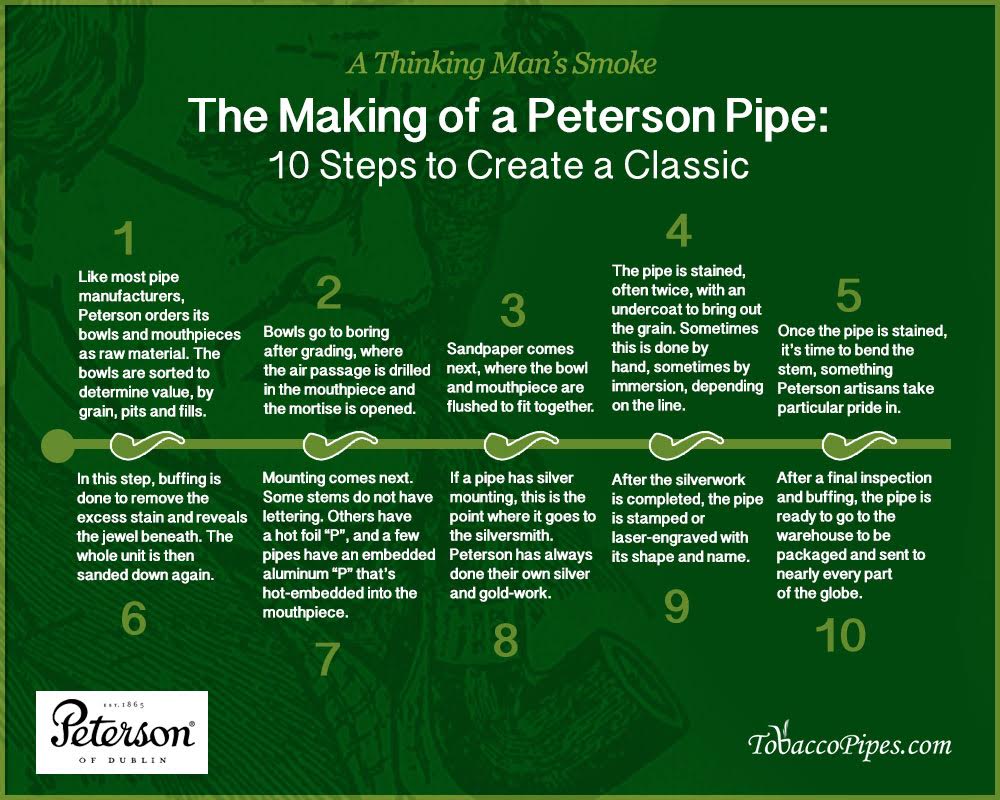

We devote an entire chapter to the craftsmanship behind the Peterson pipe, with detailed text and illustrations of how the pipes are made, as well as photographs going back to the 1890s. Sometimes the process gets a little complicated. The 150th Anniversary video does a great job visually going through the basic steps. Here’s a basic outline of most of what you see:

First, like most pipe manufacturers, Peterson orders its bowls and mouthpieces as raw material. The bowls are sorted to determine their value, by grain, pits and fills. Pricing is based on the grade of the bowl and add-ons like sterling silver, not finishing as some people believe.

After the bowls have been graded, they go to boring, where the air passage is drilled in the mouthpiece and the mortise is opened.

Sandpapering comes next, where the bowl and mouthpiece are flushed to fit together.

Next, the pipe is stained, often twice, with an undercoat to bring out the grain. Sometimes this is done by hand, sometimes by immersion, depending on the line.

Once the pipe is stained, it's time to bend the stem, something Peterson artisans take particular pride in.

Afterwards comes the buffing, which removes the excess stain and reveals the jewel beneath. The whole unit is then sanded down again.

Next comes the mounting. Some stems do not have lettering. Others have a hot foil “P”, and a few pipes have an embedded aluminum “P” that’s hot-embedded into the mouthpiece. When your pipe has the latter, you know it's a higher-grade Peterson.

If a pipe has silver mounting, this is the point where it goes to the silversmith. Peterson has always done their own silver and gold-work, and even cut and soldered their own nickel mounts before the 1960s.

The pipe is stamped or laser-engraved with its shape and name at this point.

After a final inspection and buffing, the pipe is ready to go to the warehouse to be packaged up and sent to nearly every part of the globe.

The Peterson Experience

Renia: I get a sense that working for Peterson is a singular experience. Can you give me a sense of what it means to be a Peterson employee?

Mark: Just like every pipe matters, with Peterson, I’d say every person matters.The employees at Peterson are a family and each member plays an important role. When they lose someone it’s a big deal, and many employees have a work history with the company of thirty, forty or fifty years or more. For instance, when Angela Fortune retired, no one really took her place. There is an organic, artisan quality to work there – people are allowed in many ways to grow into their work, which may change over time.

If someone dies without training up a replacement, not only has the individual been lost, that skill disappears or is greatly diminished. The employees on the floor primarily learn through an apprenticeship, which takes about five years. When we were there in 2013, they were training a young man in stem-bending and he would constantly check with his supervisor. The supervision was constant and critical. It’s a fascinating process to watch.

Tom and now his son Conor, who joined Peterson a few years ago, spend a lot of time on the road, but they know the value and importance of communication and communion. The whole Peterson team seems uniquely in synch with one another.

Renia: That sounds incredible and very foreign to what most Americans are used to their work days looking like. What does a typical day look like for you? Doing this part-time, it seems like you must give it all your free time!

Mark: When I get home from my day as a teacher, I work on the book as I smoke – often accompanied with a Peterson “setter” like the Sherlock Holmes Hopkins I bought from you – until my dogs come tell me it’s time to stop. I spend the rest of the evening reading, smoking, and tossing dog toys over the sofa. My days are filled with great books, good students, pipes, tobacco, and prayer. It’s not a bad way to live.

We couldn’t agree more.